First, James Failed More than Five Thousand Times. Then His Invention Sold Billions

When you hear the brand "Dyson," you probably think about some futuristic-looking fans or vacuums. Founded by Sir James Dyson, Dyson is a British technology company that innovates household appliances with modern engineering and design. From bagless vacuums to bladeless fans, Dyson's products continue to impress consumers.

And Dyson has reaped great rewards for it — he's among the United Kingdom's wealthiest. But before the Dyson vacuum's massive success, it took five years and thousands of failed prototypes. 5,127, to be exact. Keep reading to learn how Dyson's iconic vacuums and fans started with a hint of frustration followed by a great idea.

Dyson Highlights

Company History

Dyson started as a one-man venture without a formal engineering or business degree. Today, he employs skilled engineers and masters of their fields. From creating cyclonic chambers to bladeless fans, Dyson's brand name continues to impress. Here's how it started.

Dyson’s early life and school

Born in 1947, Dyson grew up in the country of Norfolk. Dyson's father died when he was nine years old. Coming from a family of creatives and academics, many thought he would follow the same pathway. And for a time, he did. He studies art and different languages in school. However, he felt frustrated that art actually meant the study of art — not producing it.

Still, at 19, he decided to pursue the liberal arts. He attended Byam Shaw School of Art. There, he met his future wife, Deirdre. He found interior design fascinating. He passed an exam and decided to study furniture design at the Royal College of Art (RCA).

"At school, I opted for arts, put off by all the formulae in science. There was nothing that combined the two like design engineering does. I only stumbled on engineering by accident and immediately decided what I wanted to do – make things that work better." Dyson said.

Before vacuums, there were watercraft and wheelbarrows

While studying at RCA, Dyson started working for Jeremy Fry, a British entrepreneur. Together, they worked on building an amphibious high-speed landing craft. He didn't have any engineering or welding experience — he picked these skills up as he went.

After completing the design, Fry and Dyson started a company and sold them. The landing craft featured a smooth fiberglass hull. The pair called it the "Sea Truck." Eventually, they were selling 200 boats per year.

Back at school, Dyson used the Sea Truck's design as his thesis project. After achieving his degree in interior design in 1970, he became the department head and sold Sea Trucks.

Soon, Fry and Dyson started developing more innovative projects. One of them included redesigning the wheelbarrow. Dyson took the standard design and replaced the traditional wheel with a plastic sphere. We imagine that is what inspired the name "Ballbarrow." And it was a huge success. One year after launching in 1974, the company was selling 45,000 units per year.

Unfortunately, a knockoff Ballbarrow launched in the U.S. market before Dyson could expand overseas. An employee stole the idea and pitched it to a Chicago-based plastics manufacturer. (We wonder if the Ballbarrow made it to the U.S. if that's the product that propelled him to fame.)

But it was only a minor setback. After the Ballbarrow, Dyson started looking to develop the iconic vacuum we know today.

The iconic vacuum we all know

Dyson started playing with the idea of a bagless vacuum cleaner in 1979 — undoubtedly his claim to international fame. The idea behind the bagless concept was pure frustration.

Traditional vacuums were often prone to diminished suction power. The vacuum's bag pores would often clog up with dirt and dust. This reduced the amount of air passing through the bag, reducing the vacuum's effectiveness.

That's when Dyson thought about getting rid of the bag entirely.

The inspiration for adding a cyclonic separator came from Dyson visiting an industrial sawmill. The sawmill used a cyclonic separator to remove dust from the air. He wondered if that same concept could scale down to accommodate an everyday vacuum.

So he got to work on building prototypes… over the next four years. He built 5,127 prototypes experimenting with two cyclones for separating the dust and grime sucked up. After finalizing the prototype, Dyson called this concept the "Dual Cyclone," and he named it the DC01. It was bagless and could sweep even the tiniest dust particles to the interior perimeter. That meant no clogging. No annoying bags. And full suction power all the time.

Getting Dyson on the market

Despite finally building a truly innovative product, Dyson found it challenging getting his vacuum on the market. Domestic appliance manufacturers wouldn't want his unique vacuum.

So, he looked overseas. During the 1980s, Dyson licensed his vacuum to Amway, a U.S.-based consumer products maker. But Amway backed out and then released their own version of a dual-cyclone vacuum cleaner. (He sued the company for patent infringement, but both parties dismissed the lawsuits).

Then Dyson tried pitching his concept to Hoover, the leading vacuum retailer in Britain. However, they wouldn't even entertain his idea until he would surrender all rights to his invention to Hoover.

If everyone says no, do it yourself

Several years after finalizing his bagless vacuum, Dyson now had to overcome this hurdle. When manufacturers and retailers refused him, Dyson didn't give up. Instead, he decided to do it on his own. He became his own manufacturer. He took out a loan for $900,000, putting his home up as collateral.

Dyson set up his manufacturing factory in Britain to produce the Dual Cyclone DC01. By 1993, he was officially selling his vacuums. Within just one year, his vacuum became the best-selling vacuum, surpassing Hoover.

What was interesting was the vacuum's price point. Dyson priced it at $399. This high price point was another reason why retailers were hesitant about carrying it in their stores. At the time, the British economy was also undergoing an economic setback.

Yet, people were still purchasing Dyson vacuums. They were fascinated. For one, the vacuum had a clear design. Unlike regular vacuums with colored exteriors, the Dyson allowed you to see all the dirt and grime the machine sucks up. Salespeople thought nobody would want to see all that gunk buildup. However, it was a design element that consumers found new and exciting.

Expanding into the United States

In 2001, Dyson hired Martin McCourt to head the company as CEO. Dyson realized his talents lay in innovation and design — not business strategy. He left that work to his talented employees so he could do what he does best. McCourt helped the brand gain popularity within the United States.

Best Buy was the first national chain to sell one of Dyson's vacuum cleaners. After David Kielly, Best Buy's merchandise manager, tried the vacuum for himself, he pushed to start selling the Dyson DC07. Like many consumers before him, Kielly liked seeing the vacuum bin filling with all the dust and debris.

By 2002, Best Buy sold ten times more vacuums than it initially projected. Eventually, other retailers started carrying these vacuums, including Home Depot, Target, and Bed Bath & Beyond.

Dyson's expansion into the U.S. confirmed another suspicion. People love technology. And consumers are willing to pay more for a product that delivers a unique experience. Even if something as mundane as an everyday cleaning item.

Dyson also made fans cool

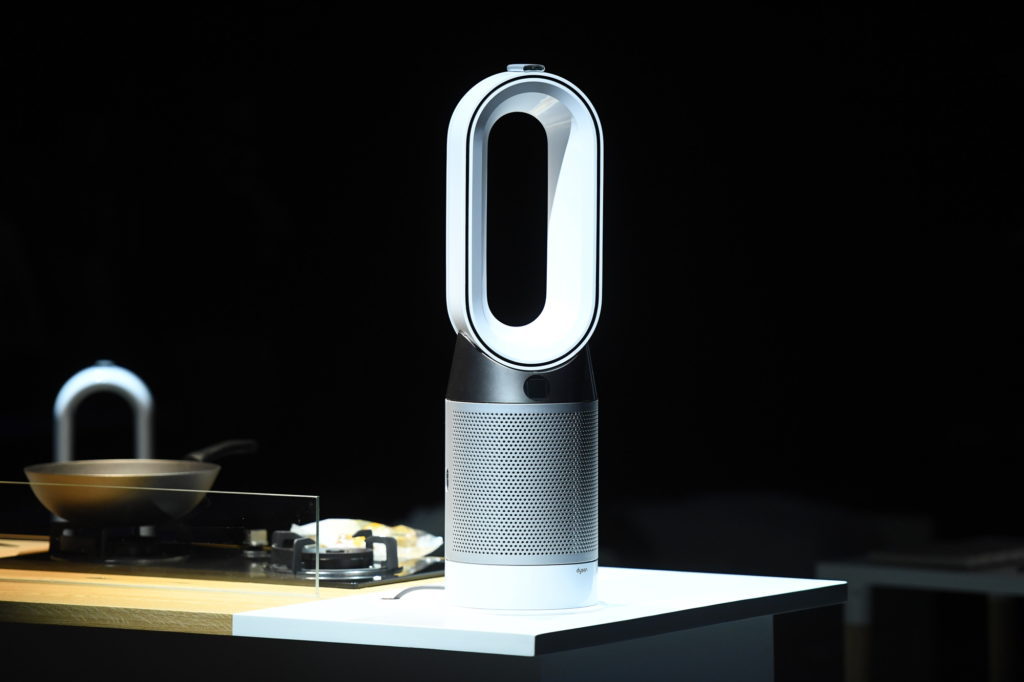

After vacuums, Dyson got to work on another everyday household item — fans. In 2009, the company launched the Air Multiplier.

The design difference was noticeable. Gone were visible fan blades and the grille (that would accumulate so much dust over time). Instead, the impeller blades are smaller and hidden in the machine base. The impeller sucks air through the base and then projects it through the rings. According to the company, the volume of air projected is 15 times greater than the air sucked in. (Novel engineering, right?)

By 2010, Dyson commanded 23% of the market. He was an industry leader and a famous household brand. Some might even say he made cleaning pretty cool. In 2011, the brand was generating $1.5 billion in annual revenue and employed 4,000 people.

What's Going On Today?

The current stats are impressive, to say the least:

Here are some other interesting things going on under the brand.

Coronavirus and air purifiers

In April 2020, the company launched the Dyson Pure Humidify+Cool in the United States. This air purifier has been uniquely engineered to purify your room throughout the year. It captures 99.97% of air pollutants. Also, it kills 99.9% of bacteria in the water to ensure your hair is being humidified and purified hygienically.

Combatting COVID-19 was one reason that inspired the Dyson air purifier. Dyson wanted to do what he could to support the United Kingdom National Health Service (NHS) during the pandemic. The company spent $24 million (without government aid) to progress this project. While these air purifiers don't specifically eliminate the virus, people can enjoy homes with cleaner air.

Packing up and moving to Asia

In 2019, Dyson announced that the company headquarters would be moving to Singapore. He explained his decision, saying that Asian markets were among the best:

"Asia is the fastest-growing market in the world and already accounts for 50 percent of our sales. Asians love new technology, that latest thing, and absolutely 'get' design," he told Robb Report. "If you are designing things for people in Asia, you should be in Asia . . . It would be arrogant to think that we can imagine products for that market sitting here in Wiltshire."

Dyson also announced plans to recruit 250 new engineers to their Singapore headquarters. The increased engineer account would double the company's software and electronics engineering teams. Dyson also stated that he'd establish a cybersecurity research center in Singapore.

The car we wish happened

Dyson recently scrapped plans for a car, noting that their prototypes simply were not commercially viable. We're a bit disappointed because we're sure that the car would have the engineer's unique thumbprint.

Unfortunately, it was a significant loss for Dyson. He'd spent approximately $610 million of his own money on the car project. Dyson is a private company and did not take any outside investment.

But there was some silver lining to the project. Dyson's battery engineers spent decades working on a high-power and quick-charging battery. The lithium-ion pack that would power the cars could deliver 600 miles on a single charge, Dyson told The Sunday Times. The battery technology is still useful and may show up in future projects.

About 500 people were working on the car project. Many of them stayed on board to further research batteries, robotics, and more.

Nurturing the Next Generation

Dyson's impressive career has garnered him an impressive net worth and brand recognition. He now uses his position to empower young minds to pursue engineering and design.

James Dyson Foundation

He founded the James Dyson Foundation in 2002 to encourage youth interest in problem-solving. This charity offers monetary awards, education programs, and teaching materials. It's also a mentorship program that helps nurture young, creative minds. The foundation currently operates in 27 countries. Dyson expanded the foundation to the U.S. in 2011 and then to Japan in 2016.

James Dyson Award

The James Dyson Award is an international student design award given to young minds that create solutions to modern problems. The goal is to encourage more young people to pursue the technical sciences, especially engineering. For the 2021 competition, there are four prizes:

The brief for this year's competition is simple. Students need to design a product that solves a problem. The judges evaluate submissions based on "clever yet simple engineering principles."

Examples of submissions include Chillax, a compact camper with a mobile kitchen galley that makes it easy to travel. And Body Voice, a wearable instrument that dancers wear to create music through their movements.

Dyson Institute of Engineering and Technology

You'd think the foundation and award would be enough, but James founded his own institute. This program aims to teach the next generation of engineers. It provides young minds with a passion for problem-solving and the resources they need.

Students attend this institute to work towards an engineering degree. Even better, they get hands-on experience. Students also work as engineers at Dyson's Research, Design and Development department.

What Entrepreneurs Can Learn

What can we learn from a guy who failed over 5,000 times before developing a bagless vacuum? Quite a lot. Here are some worth noting:

Know the problem, sell the solution.

Before the Dyson vacuum, vacuums with bags with the norm. Yet, the "normal" way isn't always the best way to get things done. Dyson experienced that firsthand. His Hoover Junior vacuum was poorly designed. The bag pores would constantly get clogged, reducing suction power. For a machine with two jobs: sucking up debris and storing it, traditional vacuums were failing at both.

"I usually sell from the point of view of frustration, hoping that other people feel the same way. After that, I was like any other vacuum cleaner salesman. I showed what it did, why it was different, and why it performed better."

After experiencing all the frustrations himself, Dyson understood the exact pain points he needed to tackle. His completely bagless vacuum used new technology. Instead of just storing debris in a bag, it whirled around within the vacuum interior like a centrifuge. The transparent storage design allowed consumers to see it for themselves.

So, when you're thinking about what physical product you want to sell, always approach it from the point of view of frustration. Identify the pain points. When selling your product, the benefits you highlight address those consumer frustrations.

Improve. Repeat.

5,127 times. That's how many times Dyson failed before finalizing his prototype for the first Dyson vacuum. Like Thomas Edison, who failed 10,000 times before inventing the light bulb, Dyson put in the work. Dyson failed and failed over and over again. But each time, he learned what to do differently or better.

"It's when something fails that you learn. If it doesn't fail, you don't learn anything. You haven't made any progress. Everything I do is a mistake. It fails. For the past 42 years—I've had a life of it," Dyson told Wired.

That's persistence. And for entrepreneurs, you'll need a lot of it. Your business idea may not immediately take off as you hope.

Maybe your market research shows that your intended product isn't in demand. Or perhaps you're selling it, but your return rates are high. Something might need tweaking, whether it's the product itself or its marketing.

Entrepreneurship demands a lot of fine-tuning along the way. Yet, each modification is a step forward in building a lucrative business of your own.

Hire to offset your weaknesses.

Don't think that being an entrepreneur always means being stuck in some managerial or director position. If administrative leadership positions aren't your strong suit (or preference), you don't have to take them. Dyson certainly didn't.

"I didn't enjoy being CEO that much," Dyson told Jonathan Gifford. "At an operational level, that becomes an enormous job, too big for me. I've never really been a businessman."

Instead, Dyson wanted to double down on what he was best at engineering and design. "I wanted to carry on the design and engineering myself. That's what I love doing," Dyson added.

Similarly, entrepreneurs can hire to offload responsibilities they don't like. As they say, horses for courses. Let people who are experts in their fields handle those types of duties. Marketing experts handle marketing. Engineering and design experts handle product research and development.

Don't play the price war.

Before Dyson's bagless vacuum entered the market, many vacuum-cleaner companies engaged in a price war. They would manufacture cheap vacuums and sell them for less than $100. These companies followed a low-price, high-volume business model.

Here's the problem with a price war. When you sell your product based on how much cheaper it is than the competition, you lose. Undercutting is a flawed business model. Why? Because it's a race to the bottom.

So, when Dyson introduced his new vacuum at the $400 mark, the pricepoint shocked many retailers. Who would spend $400 for a vacuum when they need another for less than a quarter of that price.

But Dyson did. How?

Like Aaron Krouse, founder of Scrub Daddy, Dyson didn't play the price war. Dyson's price point represents the value a Dyson vacuum offers.

Dyson delivered an innovative product that consumers wanted. Dyson vacuums did away with clogged bag pores that reduced suction. It also looked cool. The clear container made it satisfying to see all the dirt you vacuum.

Consumers believed the value justified the higher price point. And they were willing to pay for it.

Let engineering lead the design.

Part of the Dyson company culture is that he does not place engineers and designs into separate buckets.

"We don't have industrial designers. All our engineers are designers, and all our designers are engineers. When you separate the two, you get the designers doing things for marketing purposes rather than functional reasons." Dyson told The New Yorker.

Engineering is what leads the design, he added. We liked this. Because it indicates that a product should, first and foremost, work. Without a functioning product, you don't have anything.

Even if you attempt to sell it, you won't find success. Customers today are savvy. And no amount of bells and whistles can make an inferior product great. Sell a subpar product, and you risk unhappy customers and a tarnished brand reputation.

Patents protect entrepreneurs and inventors.

Wired asked Dyson for his thoughts on patents stifling competition and innovation. Specifically, would an open-source design be better for everybody? Dyson had an interesting answer.

Patents actually increase competition, Dyson explained. Entrepreneurs and engineers, and innovators put in tons of time, effort, and capital developing solutions to problems. If you want to nurture these bright minds who invent, innovate, and improve, you need to protect them. Patents are one form of protection.

There is also a limit to what you can patent. "You can't patent something that another skilled engineer in the field could have calculated or done with his basic knowledge," Dyson added. Only genuinely unique and innovative concepts are eligible for patents.

Also, patents force innovators to brainstorm ways to do even better. "If someone has a good idea and a competitor can't copy it, then that competitor will have to think of their own way of doing it," Dyson explained. "So then, instead of just one innovator, you have two or three people trying to do something in a new way."

You don't need a formal education to solve problems.

It's worth noting that Dyson went to school in the liberal arts. He didn't study business. Although praised as a pioneer in engineering consumer household products, Dyson doesn't have a degree in engineering.

Yes, there are some barriers to entry for becoming an entrepreneur. However, that does not mean they're insurmountable.

You don't need a college degree to start figuring out ways to solve problems. You don't need a traditional bank loan to kickstart your business. Crowdfunding and bootstrapping are available to those who want to work for it. And you certainly don't need to grow up in a family of entrepreneurs to become one.

Entrepreneurship is available to anyone willing to put in the time, grit, and research.

Dyson FAQs

What is the net worth of James Dyson?

James Dyson's reported net worth is an estimated $10 billion, according to Forbes. Dyson is also ranked fourth on Forbes' list of the ten richest U.K. billionaires.

Is Dyson a public company?

No, Dyson is a privately-owned enterprise. There is no Dyson company stock trading on any listing. The company has not made any announcements about going public.

Is Dyson a Japanese company?

Dyson is a British technology company with research and manufacturing sites in Wiltshire, Malaysia, and Singapore. Dyson's global headquarters are currently located in Singapore.

Where is Dyson made?

Dyson has manufacturing locations in Singapore and is extending to Malaysia and the Philippines.

Why is Dyson so expensive?

When consumers purchase a Dyson product, they're purchasing clever engineering and thoughtful design. The technology company invests heavily in research and development. Before a product goes to market, engineers heavily test the product for performance and durability. Engineers have scrapped entire batches if a product is not worthy, one engineer told Mashable.

The Bottom Line

Dyson said something that resonated with us:

"You see some big problem — something that has a big Achilles' heel — and you can then proceed in one of two ways. You either develop a technology to solve the problem, or you happen to come across a technology that solves the problem."

Dyson said that "you" solve the problem. Not somebody else and certainly not big government. We believe talented individuals create the best solutions to society's problems. Entrepreneurs, inventors, and engineers are the true innovators — not bureaucrats and politicians. Entrepreneurs, like Dyson's engineers, are always seeking and creating better solutions to modern challenges.